Late last night I climbed aboard the northbound bus headed for the boat. And twelve very uncomfortable hours later I stumbled outside again in Guaymas. Another short bus ride and I was at the boat, which had just recently been moved into the work yard to have the bottom painted and to get the engine put back together again.

Unfortunately the mechanic with most of the engine in the back of his truck never got away from the other job he was doing today and left me in the lurch. Mañana.

I worked on other things. I got the new alternator installed. It just needs a bit of wiring to finish it up.

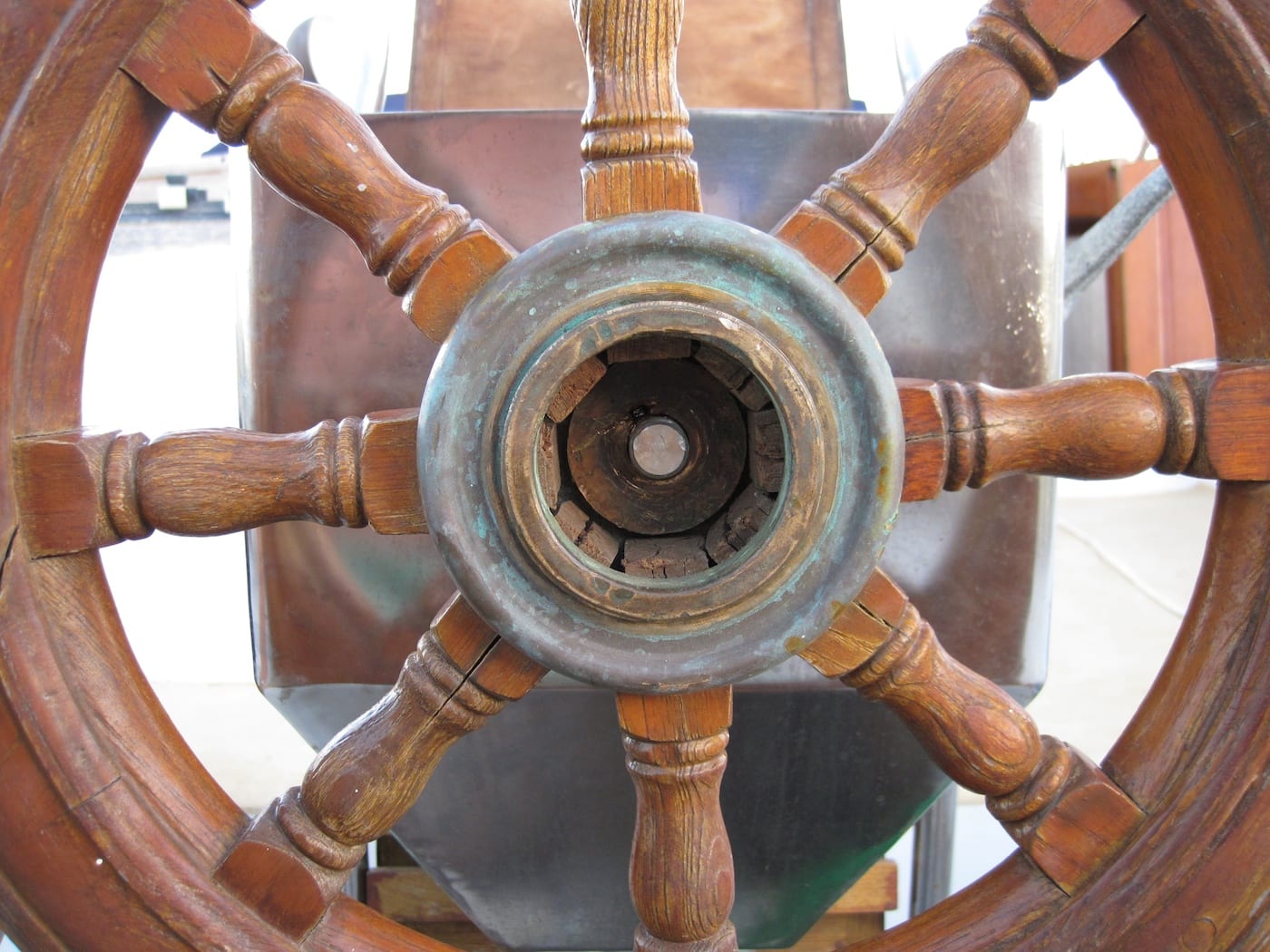

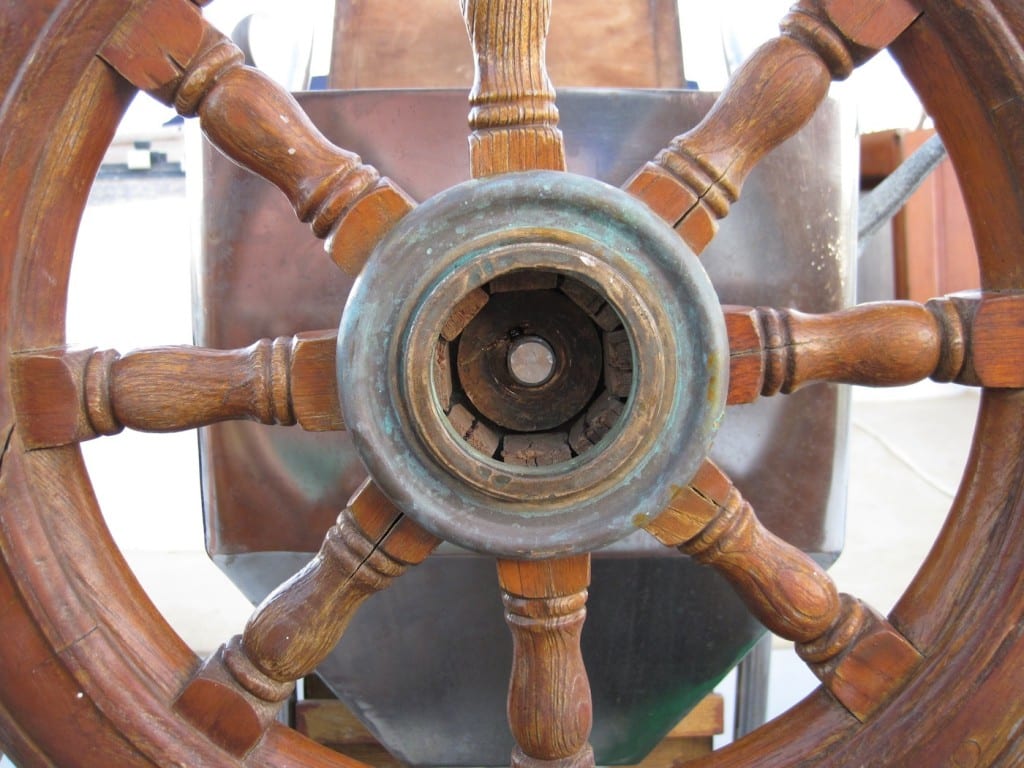

I also worked on this damn thing—without any success. The steering wheel needs to come off in order to replace the oil o-ring seal that has completely failed now in the heat. I however could not for the life of me get this wheel off.

How does it come off? Whoever answers this question correctly wins the internet. Please refrain from the obvious. Despite appearances I am not an idiot (though the answer to this question may prove otherwise). I know it looks like a metal pin needs to be pushed out through that square gap, but that metal in there isn’t moving. It also doesn’t appear to have a “track” to slide in and out on. The wheel won’t move forward or backward either. It seems like maybe I need to access the metal “pin(?)” from the top, but that requires drilling out the teak screw caps for the screws that are holding the steering wheel spokes in—and that just doesn’t seem right to me. Lastly, I’ve tried looking at our other wheel for help, but same problem. I’m lost.

27 Comments on “Steering Wheel”

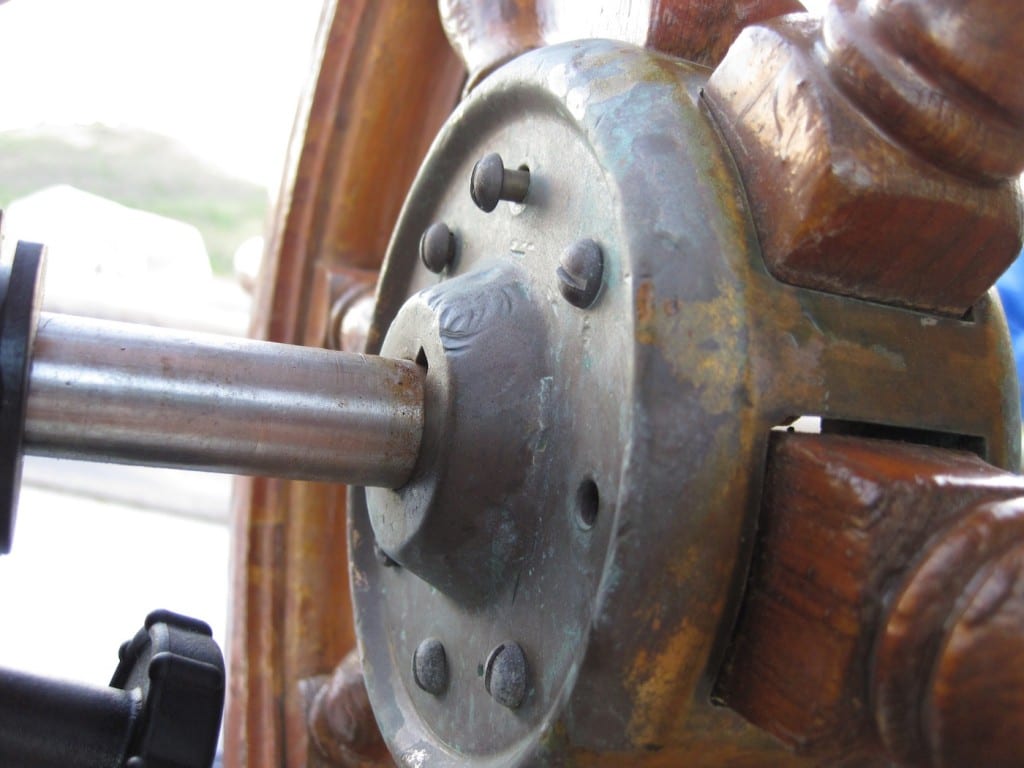

Pat… Its a stainless shaft, a brass hub, and appears to be a carbon steel woodruff key.

Normally there is a nut on the end of the shaft to hold the whole thing together… there must be a slight interference fit to keep the wheel on..

So.. theres a few ways to get it off.. correct way is a puller.. jaws go around your brass hub, and centre bolt push’s on the stainless shaft.

Second method.. tap the wheel back and forth with a hammer..

Third method.. find something like a piece of pipe, and pry the wheel off using a pivot on the binnacle.

Sometimes you need to push the wheel on a but more before it will come off..

Also helps to spray some penetrating oil or WD40 in there..

Don’t try and remove the key.. its not going anywhere… google woodruff key for pics

Don’t hit your thumb with the hammer 🙂

Timbo

Don’t suppose you have a torch… a bit of heat on the brass hub would go a long way..

Wow! That looks like it is on there tight. Push it off or pull it off? Hmmmm.

I found this interent bit: The shaft of the helm itself is steel not brass. Do not strike it with a hammer. Place a block of wood on the end of the shaft with the loosened nut still in place and strike the block off wood with the hammer while someone else applies an even pulling force on the steering wheel.

Pat, Since I’m a shade tree mechanic (and maybe not even that) I “might” get a steering wheel puller, wrap a small chain or chains around the back of the wheel, pull the chains to the front of the wheel, attach it to the puller and try to exert pulling pressure to the wheel while I tapped on the back. I would also soak it in WD-40 or some such. Just an idea for you.

Timbo wins the internet.

I was hoping you chimed in. This looks like our old wheel that you took off.

Just an FYI…be sure and cover your cockpit drains in case the woodruff key goes flying when you get the wheel loose. Mine always does.

All the above comments are good advise ,

1. Use WD40 or Coca Cola as a penetrating Oil.

2. Use a blow torch to heat the brass.

3. A puller is the ‘civilised way’ but as you are in Mexico you could use a a wooden block and a heavy Hammer .

I vote for heat and light tapping from the rear towards the end of the shaft. WD-40 is not a penetrating oil try Marvel Mystery oil or some other penetrating oil. Give the oil time to penetrate 6 hours or so. Over night would be best.

Timbo said it perfectly in his first advice and ditto on the application of heat to assist.

I have some time tested swear words if you need them.

All good advice regarding removal.

When you put it back together, may I suggest you use emery cloth (flexible sandpaper) to clean up the shaft

and copper slip (grease would do but copper slip is the best) on the shaft and thread for next time you want to do it.

Also, be careful hitting the brass to get it back on, that is probably why it is tight.

H

A trick we use at sea sometimes with stubborn interference fits is to hit the shaft with a CO2 fire extinguisher. If you have one onboard, removed the “horn” and direct the nozzle onto the end of the shaft. Let it rip, the CO2 will have a cooling effect, this induces shrinkage and hopefully breaking of the interference. VERY IMPORTANT!! You must use gloves to hold the tube of the extinguisher, CO2 will cause freezing on the outside of the tube and if you are not using gloves you will have some very stuck and painful hands.

A puller is the easiest way to do this if you have a puller that size.

You can fabricate one quite easily, you need some long bolts (two of the same and one bigger with a jacking nut), a tap for the bolt thread, and a square section of tubing or bar.

Drill two holes, equally spaced and opposite one another across the steering shaft into the brass hub. Tap these out for your chosen thread size. Now drill three holes in your section of tube, two at the ends to except the two bolts that you have setup in the hub and a center hole for bigger bolt or the “jacking bolt” A good idea is to have the bolts at such a length that the jacking assembly protrudes from the hub space for easy working. Assemble and tighten the center bolt against the shaft center. As you tighten you will start “pulling” against the hub via the other two fixed bolts.

Apply as much force as you can and hit the the other side with a hammer, it should pop off. You will have this pulling assembly for future use.

Hope you come right.

1. I have to recommend against heat in the middle of your wooden wheel. Put an ice cube on the shaft for a couple of minutes right before you start hitting, it doesn’t cost anything and it may help a little

2. I haven’t yet found any penetrating oil in Mexico, WD-40 might be your best bet.

3. It’s a tapered shaft and a tapered hub, the key just keeps it from rotating, it doesn’t retain the wheel. It’s all just stuck together.

I’ve had my best luck pulling on the wheel with my (our) hands back towards the stern as hard as possible while tapping on the shaft. I’ve freed hundreds of wheels like this when I didn’t have the right puller. I use a piece of brass between the hammer and the shaft to prevent any damage. I have a brass drift for this kind of thing.

If all else fails…Sawzall.

Timbo is correct on the puller. Try to put something behind the brass for the puller jaws to pull against. The bronze could deform before it slips. Also, squirt some PB Blaster into it and let it sit for a few.

Having the same boat and just tightening that nut, I hope I didn’t tightening too much.

Thanks everyone, I PB Blastered it and will try tapping later this morning. The mechanic is also coming today to work on the engine and I know he had a puller in his truck if we need it. Thanks again. Will report back. Timbo, you win the internet for the day.

You will need the puller, it’s the least damaging way to do it. We have the same wheel. Mostly now carry the puller to lend to other people.

FYI a 50/50 mix of ATF and acetone is the best penetrating “oil”..I use it all the time, old mechanics trick. Make batch and keep in your stores.

That wheel will only come off with a large heavy gear puller. You should find you should ask the yard if they have one. It is going to have to be big enough to go around the center ring and deep enough to get behind it. You can smack that thing all you want and it will not come loose without major damage to it. It needs lubrication and constant and significant pressure. It may actually take 1 ton of force. Make sure that you get a 3 point puller not a two point puller (how many arms it has) as the 3 point will disperse the pressure more evenly. DO NOT USE HEAT! you will only burn up the wood and it will not help you on this anyway. Be careful because when it give it might pop a few inches with tremendous force.

Looking forward to winning the internet!! when do I receive it?

Pat.

Mate – This is just another great job for a can of Blastoline.

Go to http://blastoland.com/blastoland/WHAT_IS_BLASTOLENE.html to see how it will help you.

And what are you doing giving away the innernet, dont you know Al Gore has proprietary inventors rights and only he can give away or assign what he created!

Murray in N.Z.

Build a simple device using chain/steel/hardwood/ and or all thread or even rope/line to contain a hydraulic jack. Using the business end of the jack against the shaft, the base against the piece of hardwood/steel….press the wheel off of the shaft…a reverse press if you will. A porta-power would be your very best option.PS if there are threads on the end of the shaft, protect them/press on with a 20 peso coin….

So who wins the Internet? Who do I pay my bill to?

Quick note here as I take a break from the engine. The wheel came right off with the gear puller that the mechanic had in his truck. Thanks for the input.

OMAR, The Man! You owe me a beer or two…

And people wonder what to blog about. 😉

Glad the wheel came off. I thought I was going to have to send you the VW

Brake drum puller! Good times..

I agree with the tap and pull suggestion. Another aid in getting this to work is to cool the shaft (as mentioned), and you can really get it to shrink if you can find liquid nitrogen like the product included in wart remover found in the U.S. Don’t know if Mexican pharmacies have it but if so, you can spray the shaft-equal application over the exposed surface-and it may give you enough reduction in interference to get the wheel off by tapping the shaft and pulling.